Homogenizing silo

Homogenizing silo

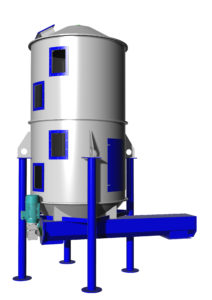

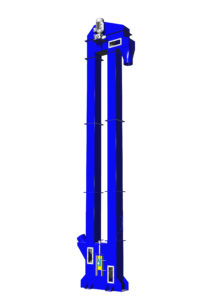

The homogenizing silo serves to homogenize a mixture of materials with similar properties and granularities, such as crushed recycled plastic or various feeds. For this reason, agriculture is offered as an ideal sector for the use of homogenizing forces. These are mainly tanks of circular cross-section, which have a vertical screw conveyor located in the axis, guaranteeing permanent movement of material by force. In addition to homogenization, such a tank performs the normal function of a stationary silo in a technological line. Homogenizing silos are usually made of painted carbon steel or stainless steel. With regard to technical needs, it is possible to combine other special materials in their production. The basic parameters of the homogenization forces include a capacity of up to 25 m3 and a homogenization capacity of less than 30 m3 / h.

The homogenizing silo serves to homogenize a mixture of materials with similar properties and granularities, such as crushed recycled plastic or various feeds. For this reason, agriculture is offered as an ideal sector for the use of homogenizing forces. These are mainly tanks of circular cross-section, which have a vertical screw conveyor located in the axis, guaranteeing permanent movement of material by force. In addition to homogenization, such a tank performs the normal function of a stationary silo in a technological line. Homogenizing silos are usually made of painted carbon steel or stainless steel. With regard to technical needs, it is possible to combine other special materials in their production. The basic parameters of the homogenization forces include a capacity of up to 25 m3 and a homogenization capacity of less than 30 m3 / h.

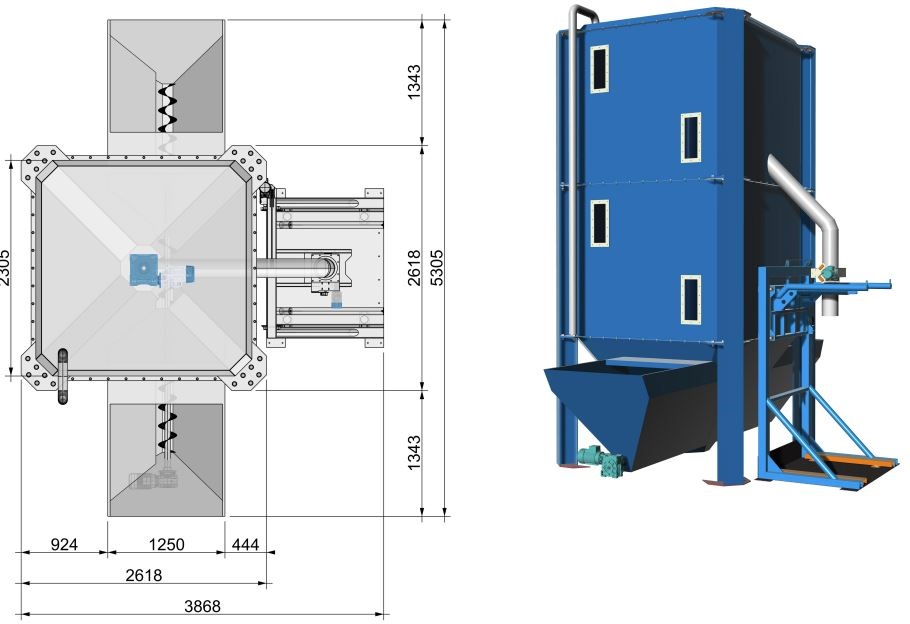

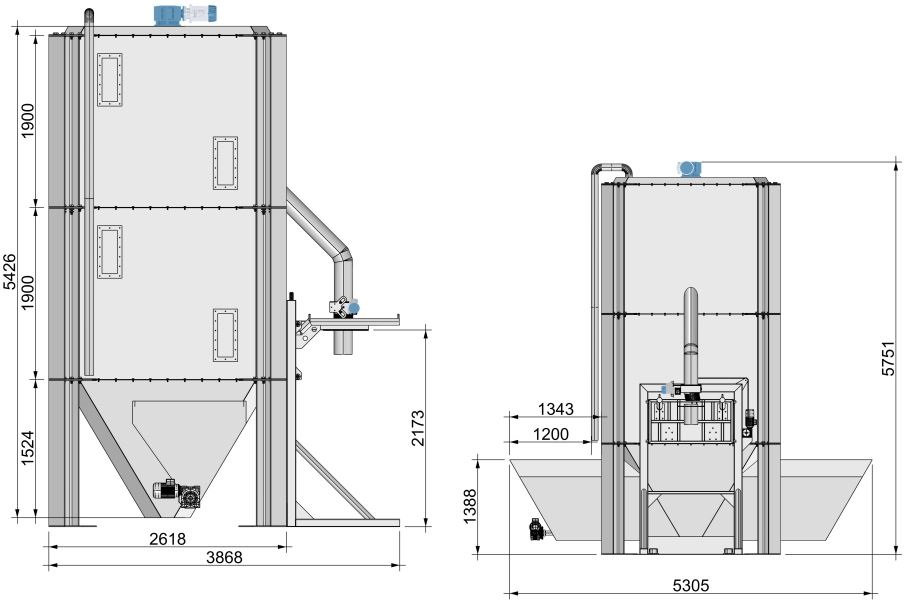

The homogenization silo can have standard dimensions, but at the same time it can be produced in accordance with the individual wishes of the customer. Homogenizing forces can be square or cylindrical, single-shell or double-shell, vertical or horizontal or non-pressurized or pressurized can also be considered. The proven manufacturer of homogenization forces has no problem ensuring the processing of all their design and production documentation, performs all the necessary static calculations and also takes care of their eventual transport, professional assembly and commissioning.

The homogenizing silo can be equipped with a number of useful components, or the silo can be combined into a series of silos with overflow of the material (filling with the 1st silo in a row, discharge of the last silo in a row).

It is possible to add other components of power equipment to the homogenization forces, which have the task of increasing user comfort. These include filters, overpressure or underpressure valves. It is also possible to purchase filling pipes together with shut-off valves, drain shut-off elements, vibration systems to facilitate emptying. The power equipment also includes technological and inspection openings and entrances, material level measuring probes, weighing strain gauges, explosion-proof safety elements, ladders of various designs, safety railings and transition and service platforms.

Technical parameters:

Photo: