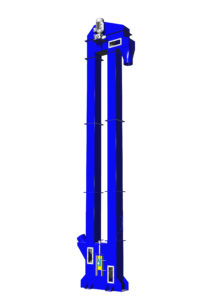

Tourniquet

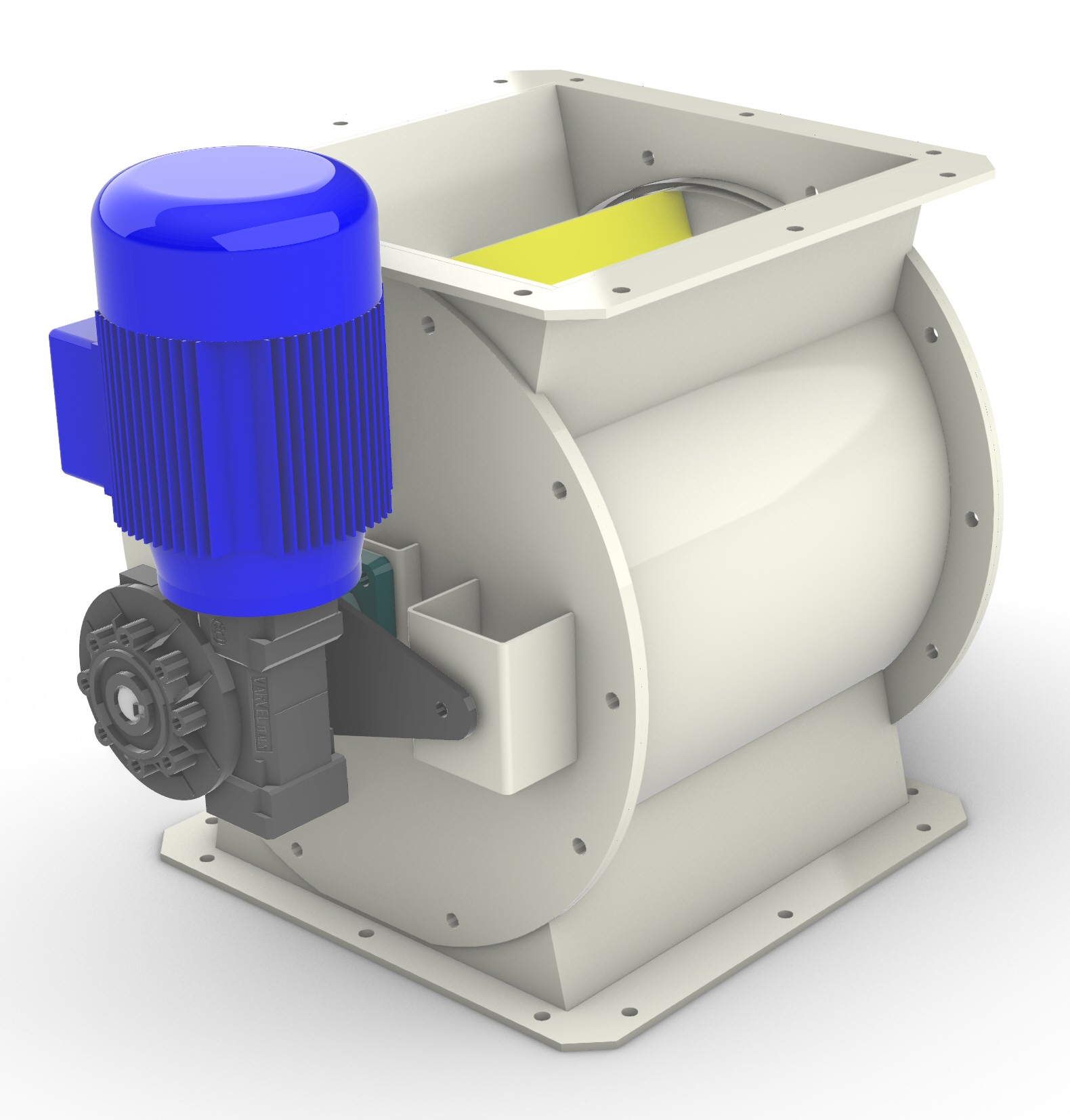

Tourniquet (rotary feeder)

Rotary feeders are used for feeding and dosing of granular or powder materials where it is necessary to pressure-separate the connected equipment or to even out the flow of material.

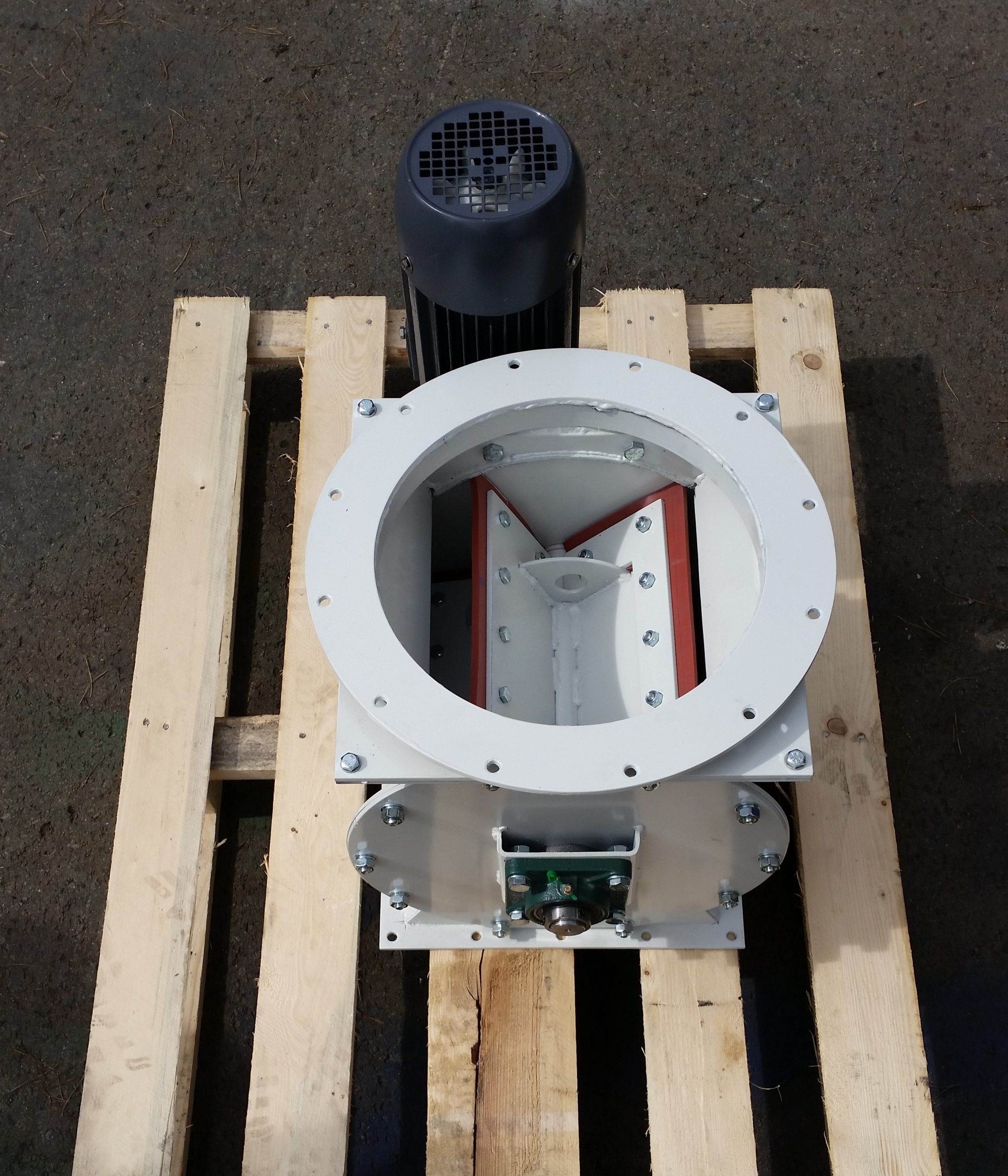

The rotary feeder transports material from the top downwards by rotating the feeder rotor. The rotor is equipped with a flexible end of the blades, which ensures the required tightness of the device during operation of the filter device. The rotor is mounted on the shaft by means of bearings which are located outside the space of the transported material. The rotor speed is ensured by a motor with a gearbox mounted on the base of the rotary feeder.

Rotary feeders are designed for the transport of loose or fibrous dust with a maximum particle size of 50 mm. The temperature of the transported material may be in the range of -20 ° C to 80 ° C. The location of the rotary feeder is possible in an environment with a temperature of – 20 ° C to + 50 ° C. The rotary feeder is designed for starting with a motor starter. The RPGG rotary feeder is certified for the separation of the interior space zone 22 with a non-hazardous area.

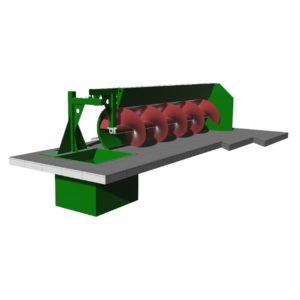

Photo: